There’s no doubt that automation plays a huge role in the future of manufacturing. In fact, an Oxford report estimates that automation in the manufacturing industry could increase $4.9 trillion every year by 2030. Here are 12 of the top automation manufacturing trends that are redefining manufacturing as we know it today—and tomorrow.

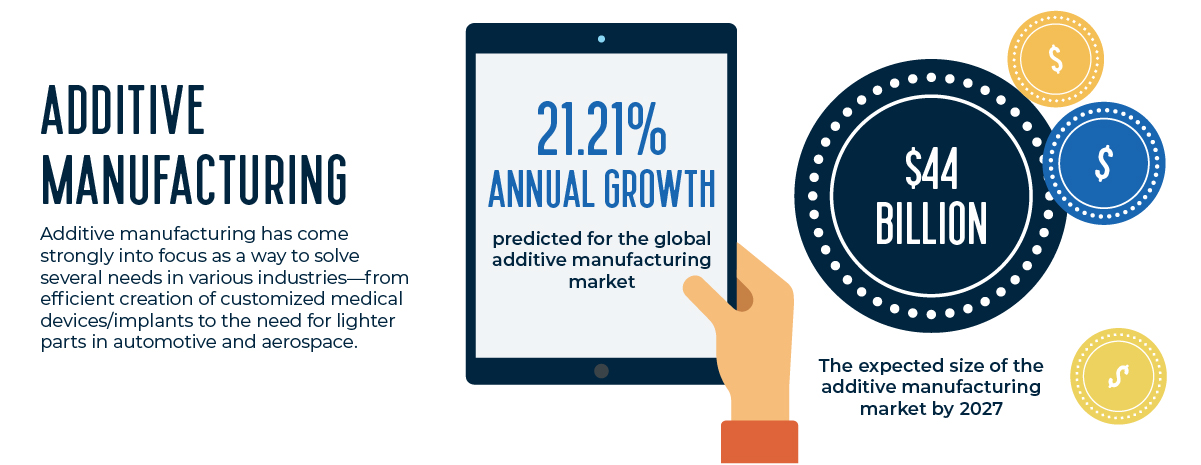

1. ADDITIVE MANUFACTURING

Manufactures today often use additive manufacturing, also known as 3D printing, to custom-build parts and products for their customers. This process requires fewer materials and creates less waste than traditional manufacturing methods. It can also be used for creating models, prototypes or components of finished products.

Want to see a real-life application of additive manufacturing? Check out how Automate exhibitor HP 3D Printing and Fast Radius helped Bastian Solutions with industrial production through 3D printing.

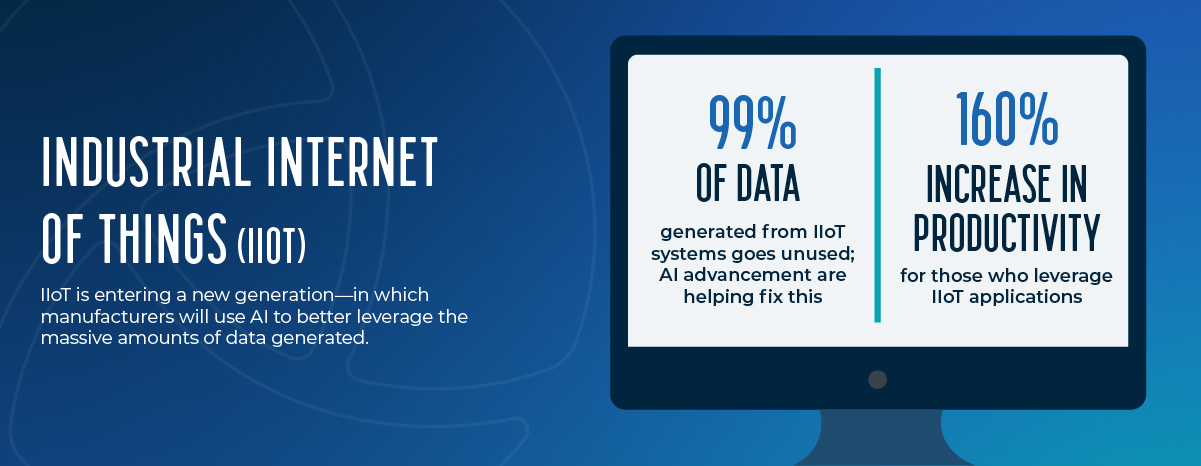

2. INDUSTRIAL INTERNET OF THINGS (IIOT)

Used specifically in manufacturing and industrial applications, this system of interconnected devices collects data that can be used to enhance the manufacturing process.

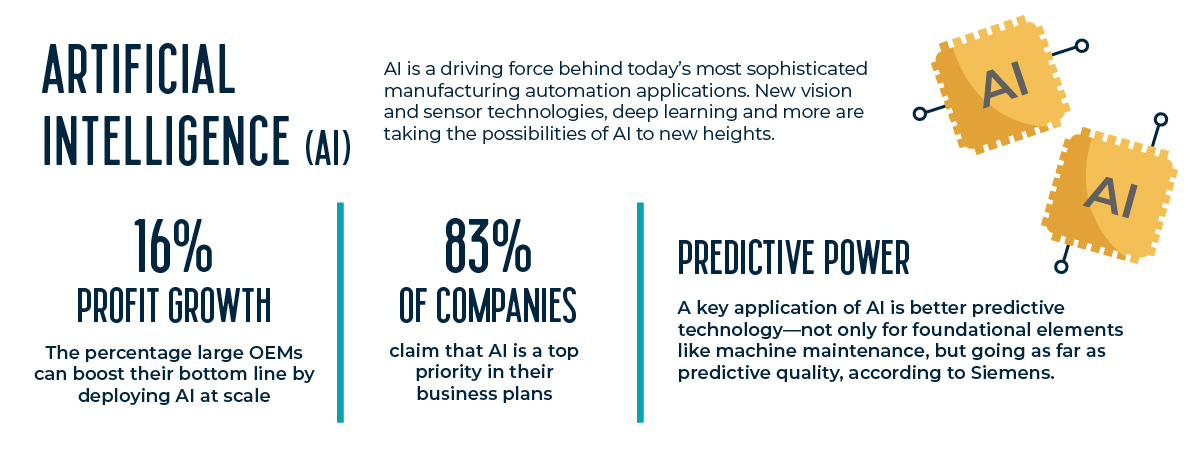

3. ARTIFICIAL INTELLIGENCE (AI)

According to Gartner, “By 2026, enterprises that have adopted AI engineering practices to build and manage adaptive AI systems will outperform their peers in the number and time it takes to operationalize AI models by at least 25 percent.”

4. PREDICTIVE MAINTENANCE

Using sensor data and AI, this maintenance method serves to detect failure patterns in machinery and parts early on so manufacturers can take preventative action.

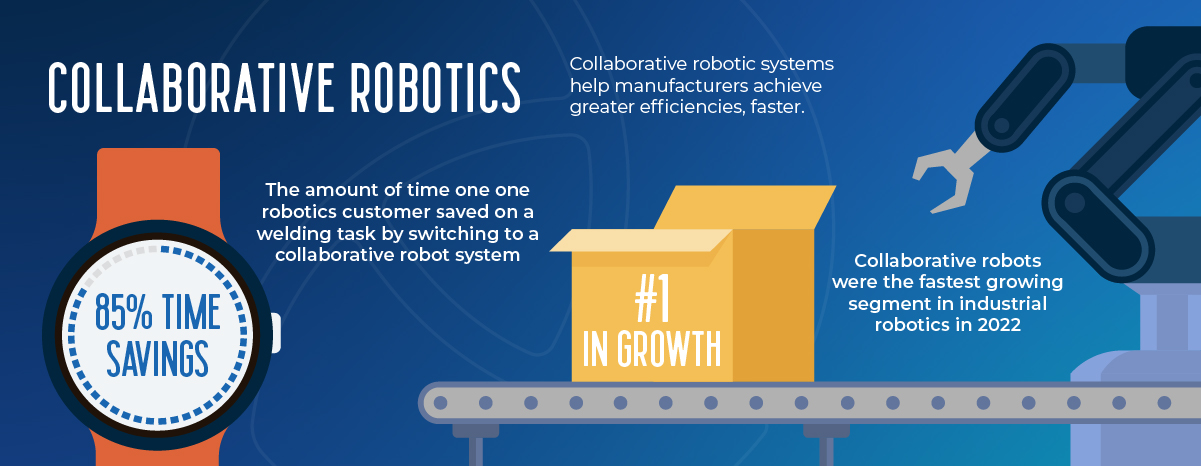

5. COLLABORATIVE ROBOTICS

Collaborative robotic systems help manufacturers achieve greater efficiencies, faster. For example, workers assisting robotic welding find that instead of spending about two weeks to program a robot to weld effectively, a collaborative robot can be programmed in about 20 minutes.

Another great example of this application is how Automate exhibitor, FANUC helped Last Arrow Manufacturing implement collaborative robots to take on simple and repetitive welding projects.

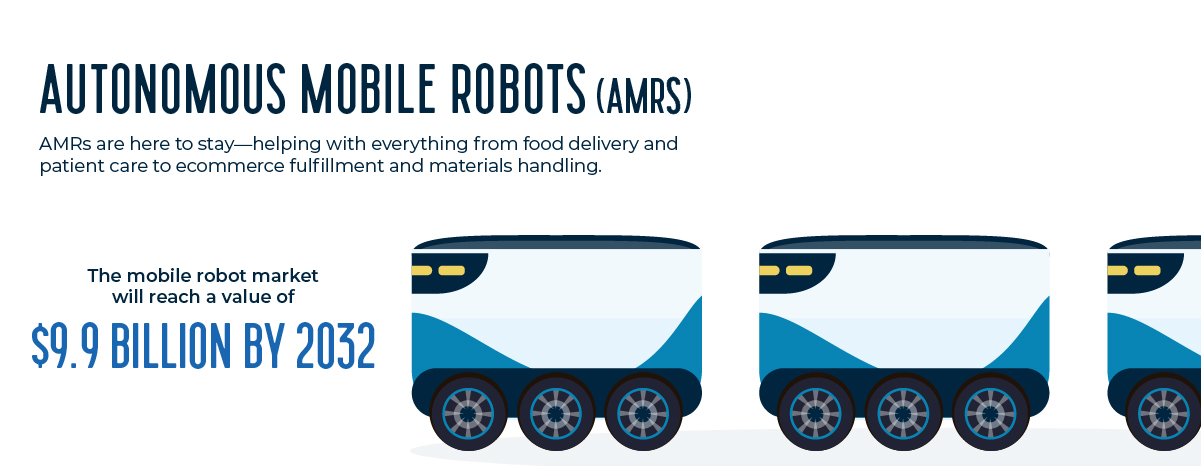

6. AUTONOMOUS MOBILE ROBOTS (AMRs)

These mobile robots relieve workers from repetitive and unergonomic warehouse tasks. Where workers are not available, they provide the materials transport capabilities required to keep operations running smoothly.

According to Interact Analysis, “the mobile robot industry grew by 33% in 2022, with more than 120,000 AGVs and AMRs shipped during the year generating $3.6bn in revenue.” The also predict shipments will continue to “grow by a further 45% in 2023 and more than 30% in 2024.”

7. MOBILE MANIPULATORS

This robot system combines a robotic manipulator arm with a mobile platform (often an AMR) to increase mobility and flexibility in the types of operations that can be completed.

8. ROBOTS-AS-A-SERVICE

With this software-based automation solution, you can easily access and operate robots with any device, creating more flexibility for your operations and potential cost savings

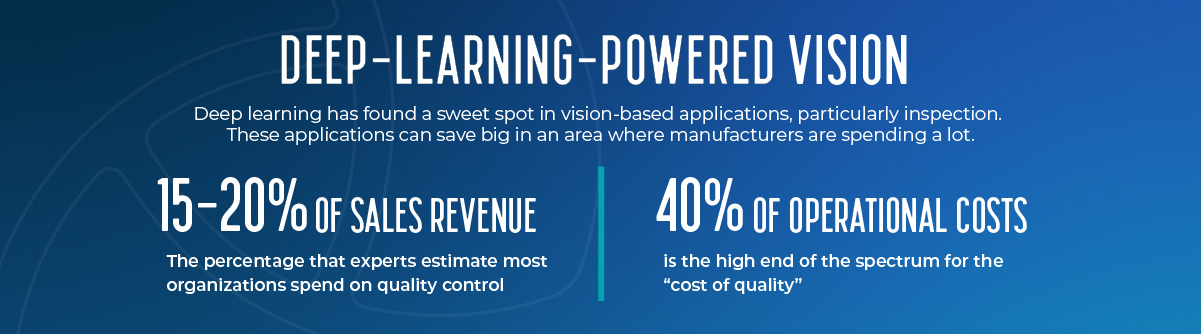

9. DEEP-LEARNING-POWERED VISION

Deep learning has found a sweet spot in vision-based applications, particularly inspection, where they outperform both human operators and traditional machine vision systems.

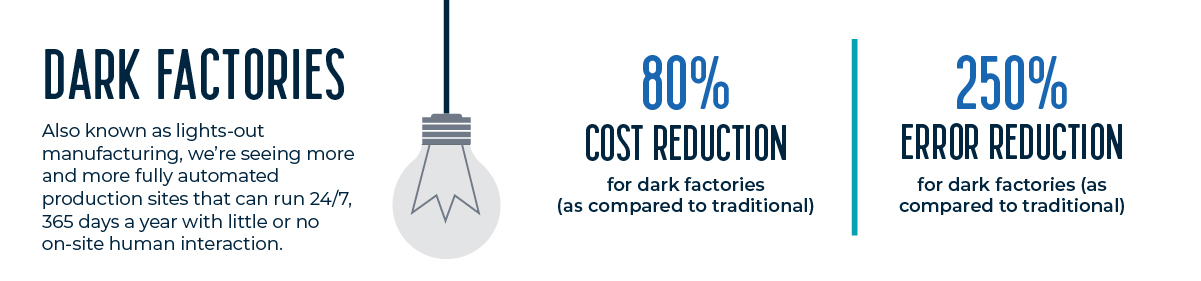

10. DARK FACTORIES

These are fully automated production sites that can run 24/7, 365 days a year without direct human intervention on site. While not prevalent today, we may see more in the near future.

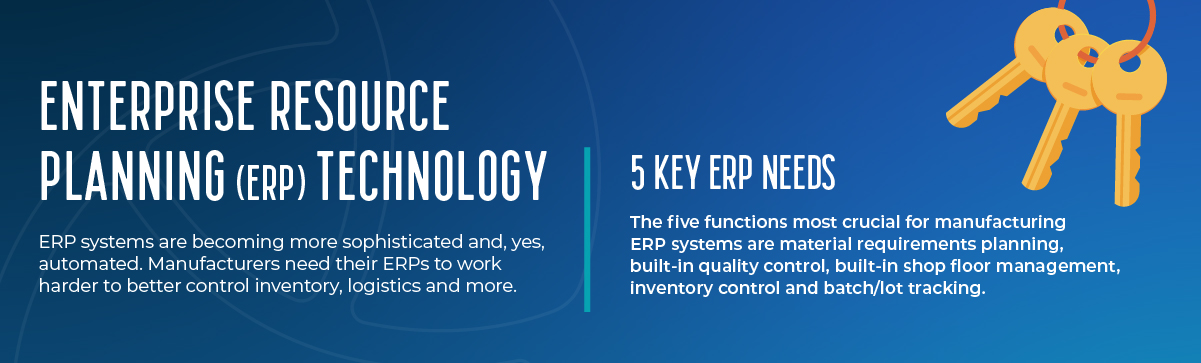

11. ENTERPRISE RESOURCE PLANNING (ERP) TECHNOLOGY

ERP systems help manufacturers automate different areas of their operations under one comprehensive system. This allows them to oversee the entire manufacturing operation and make improvements and adjustments where needed.

12. PICK AND PLACE ROBOTS

Picking robots aren’t new to manufacturing—they’re just getting smarter. These robots can grab parts in assembly settings, pack boxes in shipping facilities, organize bins, load machining tools, inspect parts and all kinds of other helpful tasks.

Want to see these trends and more in action? Don’t miss Automate 2024, the largest showcase of automation in North America, May 6-9, in Chicago, Illinois, USA. See many of the game-changing technologies mentioned above on the show floor. Register FREE today.

Sources: 3Dnatives, Research and Markets, Gartner, Forbes, Siemens, FANUC, Interact Analysis, Efficient Manufacturing/Industr.com, ASQ, CIO Insight, SAS, Industry Week

« View All Blogs