THE SHOW FOR AUTOMATION

May 6–9, 2024 · Chicago, Illinois, USA

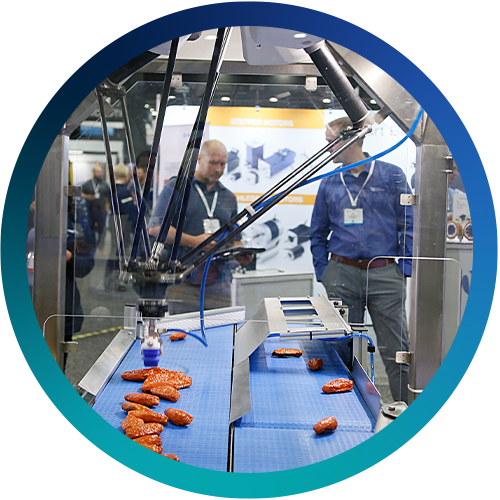

With over 800 exhibitors, our show floor hosts leading automation solutions from around the world. You’ll find everything from robotics to vision to motion control, AI and more. Join us to see how automation is no longer just the future; it’s the here and now.

EXPLORE EVERYTHING THE SHOW HAS TO OFFER

Stay tuned for more information on keynotes, Show Theater sessions and special events.

FORWARD-THINKING INDUSTRIES

Our attendees span different industries, company sizes and experience levels—from brand new to seasoned automation professionals. Look at just a few industries represented on our floor.

- Aerospace

- Agriculture

- Automotive

- Construction

- Electronics

- Food & Beverage

- Healthcare

- Life Sciences

- Logistics

- Manufacturing

- Motion Control

- Retail

- Robotics

- Warehousing

- And more!

INTELLIGENT SOLUTIONS

Want an up-close and in-person view of the incredible solutions automation has to offer? Our show floor has almost every application imaginable.

- Additive manufacturing

- Cameras & smart cameras

- Controls

- Conveyors

- End-of-arm tooling

- Frame grabbers

- Industrial IoT

- Laser equipment & systems

- Metrology equipment

- Motion control systems

- Motors

- Robots

- Safety products

- Sensors & feedback devices

- Software & AI

- Vision systems

- 5G technology

- And more!

.png)

Take Our Automation Discovery Quiz

Learn what solutions or trends can help your business get the most out of automation. It doesn’t matter if you’re just getting started or a seasoned pro—simply answer a few questions to see what’s right for you!

Show Sponsors

Our sponsors are among the biggest names in automation. See which companies are helping the event grow each year—or become a sponsor to make huge impressions on our attendees.

.png)